8

Modules

11

Minute Fast Charging

1

The Power of One

0

Zero Lock-In

800

The 800V Multiplier

Lightning Featured in The European Business Review with a thought leadership article:

The 800V Pivot: Architecture Is the Foundational Lever for EV Scalability

Electric vehicles are no longer limited by consumer demand — they are limited by architecture.

In this published article, our CEO, Richard Hatfield, explores why the transition to 800 volt systems is not an incremental upgrade, but a structural shift that determines which EV platforms can truly scale.

While much of the industry debate focuses on battery chemistry, range, or charging speed, the real constraint lies deeper — in electrical architecture.

Voltage is not a specification. It is a force multiplier. Higher voltage enables lower current, reduced thermal stress, lighter wiring, faster charging, and more efficient power delivery across the entire system.

But the shift to 800V is not simply about performance. It is about platform viability.

As automakers and mobility OEMs race to electrify multiple vehicle classes — from motorcycles to passenger vehicles to commercial platforms — scalable architecture becomes the decisive competitive advantage. Systems designed around legacy 400V constraints will increasingly face efficiency ceilings, packaging challenges, and cost barriers.

This article outlines:

Why architecture, not chemistry, is the true scalability lever

How high-voltage systems reduce system-wide losses

The compounding impact of thermal efficiency and power density

Why early architectural decisions determine long-term platform economics

Lightning’s race-proven 800V platform demonstrates that high-voltage architecture is not theoretical. It is validated in one of the most demanding performance environments in the world — and now positioned to scale beyond it.

The next phase of electrification will not be won by incremental improvements. It will be won by foundational design choices.

Read the full article in The European Business Review to understand why the 800V pivot is redefining the EV landscape.

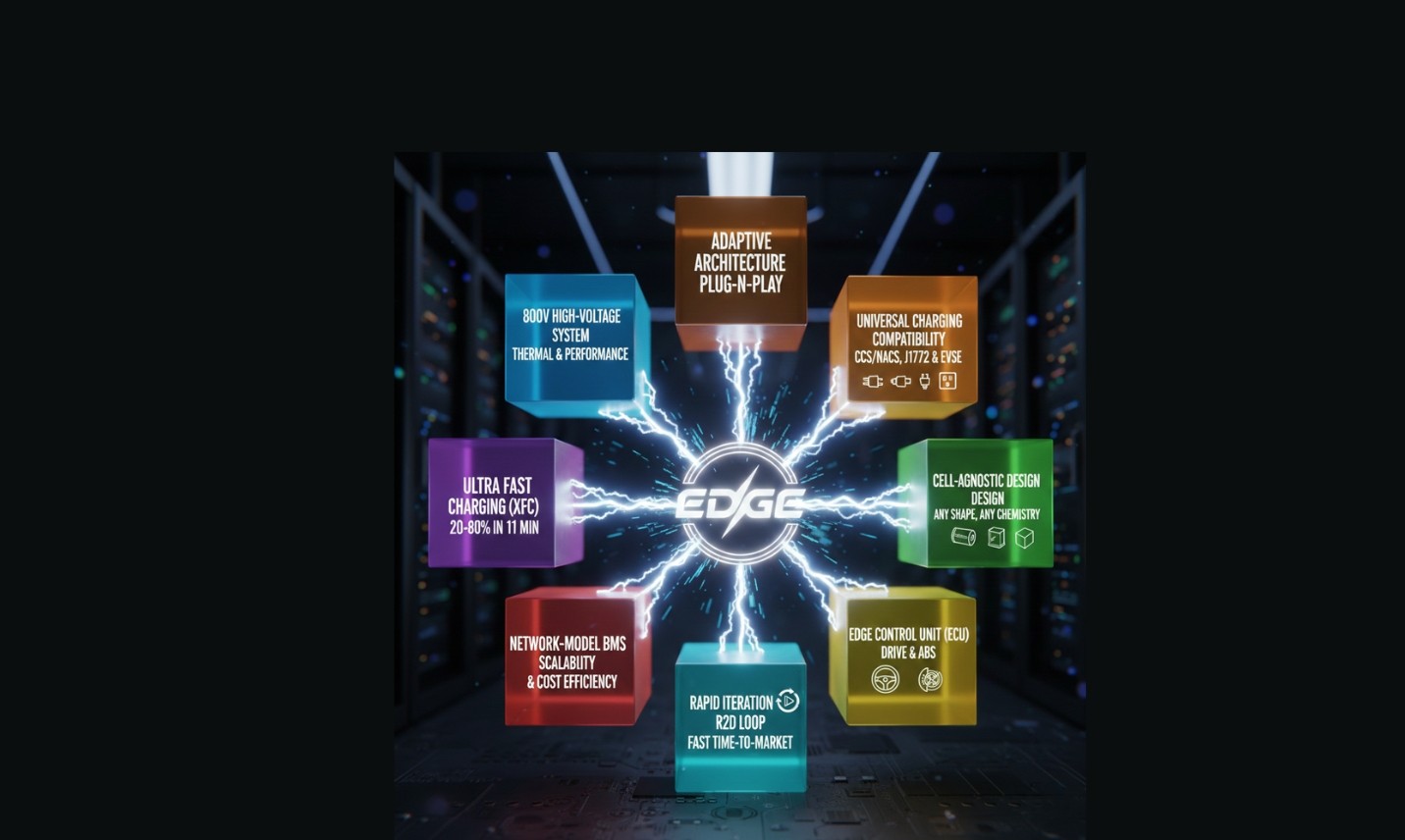

Meet EDGE, Lightning’s Modular Electrification Architecture.

Built from our record-breaking racing DNA, EDGE is designed around 8 intelligent modular “cubes” that deliver performance, flexibility, and future-proof electrification.

EDGE enables a new generation of transportation — from high-performance platforms to urban mobility and commercial applications — through a plug-and-play electrification system.

The EDGE Advantage:

🛡️ Supply Chain Resilience: Easily pivot between vendors and form factors (cylindrical, pouch, or prismatic) without a total hardware redesign.

Electrification does not need to start from scratch. It can start from a foundation engineered under real-world performance demands.

One Intelligent Platform.

Total Engineering Freedom.

At the core of the EDGE platform is a truly Adaptive Architecture. Unlike traditional “off-the-shelf” EV solutions that lock OEMs into rigid, proprietary ecosystems, EDGE is built on a foundation of independent, modular cubes.

This modularity solves the industry’s greatest frustration: System Lock-in. With EDGE, the function of a single cube can be upgraded, modified, or swapped without requiring a total system redesign. Whether you are transitioning to a new battery chemistry or updating a control logic, the rest of the architecture remains stable. This gives OEMs the ultimate competitive advantage—the ability to evolve their vehicle specs at the speed of innovation, without the catastrophic cost of re-engineering the entire platform.

At the core of the EDGE platform is a truly Adaptive Architecture. Unlike traditional “off-the-shelf” EV solutions that lock OEMs into rigid, proprietary ecosystems, EDGE is built on a foundation of independent, modular cubes.

This modularity solves the industry’s greatest frustration: System Lock-in.

With EDGE, the function of a single cube can be upgraded, modified, or swapped without requiring a total system redesign. Whether you are transitioning to a new battery chemistry or updating a control logic, the rest of the architecture remains stable.

This gives OEMs the ultimate competitive advantage—the ability to evolve their vehicle specs at the speed of innovation, without the catastrophic cost of re-engineering the entire platform

The EDGE High-Voltage System establishes 800V as the uncompromising standard for any OEM aiming for market leadership. The shift to 800V provides two critical advantages:

1. Unrivaled Performance: By doubling the voltage, we reduce current (amperage) for the same power output. This results in significantly lower heat generation, allowing for sustained high-performance maneuvers and higher power density without the weight penalty of massive cooling systems or heavy cabling.

2. True Fast Charging: 800V is the gateway to XFC. It allows the vehicle to accept massive energy loads safely and quickly, reducing 20-80% charge times to just 11 minutes.

Whether you are building a flagship hypercar, a high-speed marine craft, or an electric aircraft, the EDGE 800V system provides the thermal headroom and electrical efficiency to ensure your vehicle outperforms the competition at the track and the charging station.

The greatest barrier to EV adoption is the “time-to-fill.”

The EDGE XFC module brings Lightning’s world-class charging speeds to your vehicle program. By utilizing a native 800V architecture and advanced power electronics, we enable 11-minute charging cycles (20–80%). As part of the EDGD modular system, it integrates seamlessly with our thermal management and BMS units to ensure cell longevity and safety during high-current charging events.

From Concept to Concrete Traditional R&D is often a bottleneck, stalled by long lead times for custom integration.

The EDGE R2D Loop redefines this process. By utilizing our modular architecture, engineers can “plug-and-play” different hardware or software configurations to validate new concepts with significant shorter R&D time.

This rapid feedback loop ensures that only the highest quality, most efficient technologies reach the final product.

For our partners, this means a drastic reduction in development overhead and a clear, fast-tracked path to mass production.

The EDGE BMS (Battery Management System) moves beyond traditional battery management by utilizing a sophisticated Network-Model approach. While standard systems require unique hardware or firmware for different pack configurations, the EDGE BMS is designed to work natively with any number of cells and any pack geometry.

This Scalable BMS provides three transformative advantages:

• BOM Standardization: Use the same hardware and firmware across your entire vehicle portfolio, from entry-level models to flagship high-capacity platforms.

• Operational Efficiency: Significantly reduce R&D costs, assembly complexity, and inventory overhead.

• Simplified Support: Standardize customer service and technical training, ensuring a consistent and reliable support ecosystem regardless of the vehicle’s application

The EDGE Control Unit is the central nervous system of the EDGE architecture. It does more than just process inputs; it harmonizes the entire vehicle’s behavior.

By monitoring data from the BMS, motor, controller and thermal sensors, the E-CU dynamically adjusts the power, traction control, and ABS to ensure maximum safety and efficiency.

This high-level integration allows for a driving experience where every module works in perfect sync to deliver smooth, predictable, and high-performance power delivery

Future-Proof Flexibility: In a rapidly evolving energy landscape, being locked into a specific battery format is a liability.

The EDGE Cell Agnostic module is engineered to accommodate any battery chemistry—be it LFP, NCM, Silicon Anodes or next-generation Solid State—in any physical configuration or size. This “chemistry-independent” approach provides our partners with the ultimate supply-chain flexibility, allowing them to optimize for cost, weight, or energy density as new cell technologies become available without disturbing the core vehicle architecture.

Global Access Simplified.

Charging infrastructure shouldn’t be a barrier to entry. The EDGE Universal Charging module provides out-of-the-box compatibility with the world’s leading standards, including J1772, CCS, and NACS. Beyond high-speed public infrastructure, the system is designed to handle standard 110/220V/230V residential outlets via EVSE integration.

This native versatility allows OEMs to deploy products globally with the confidence that their customers can charge anywhere, from public charging stations to home garage.